Like any sophisticated system, CNC machines rely heavily on precise settings to function properly. When it comes to feed rate and cutting speed, setting them arbitrarily can lead to serious issues. While these two terms may seem interchangeable, they each serve distinct functions, affecting everything from surface finish to material removal rate. The success of […]

To achieve flawless results in CNC machining, grasping the significance of the depth of cut is a “must”. This parameter isn’t just a technical detail—it’s a cornerstone that affects the efficiency, quality, and longevity of your machining projects, whether you’re a hobbyist or operating at an industrial scale. Depth of cut stands out among machining […]

Boring machining is quite popular, as it’s usually used in most toolmaking shops. Its versatility makes it an essential in the manufacturing world, and what better tool to help in drilling or boring precise holes than the boring machine. Whether you are involved in CNC machining, manufacturing, or looking to improve machining services, understanding boring […]

If you’ve ever questioned how threads are made in metal parts or a workpiece, tapping is the process that makes it happen. Tapping creates internal threads, enabling secure attachment of different components. This technique is commonly used in CNC (Computer Numerical Control) machining due to its reliability in consistently producing accurate threads. This article is […]

Polishing goes beyond simply enhancing appearance—although that is often a key reason for its use. Polishing is all about eliminating imperfections that arise during manufacturing, ensuring that the final product is not only visually appealing but also functionally sound. Whether your aim is to boost aesthetics, improve functionality, or achieve both, polishing is crucial […]

Powder coating has become a popular type of surface finish in the CNC machining and manufacturing, as it helps protect metals from external influences like rusts and scratches. This technique enhances not only the aesthetic appeal but also the durability of products, making it a crucial component in various applications. This comprehensive guide focuses on […]

Plating is a widely used manufacturing technique in CNC machining and injection molding services, particularly for its ability to enhance both the durability and functionality of products. Its popularity also stems from its ability to provide surfaces with a sleek, polished appearance. If you’re aiming to improve both the aesthetic and performance qualities of your […]

CNC machining has revolutionized the manufacturing industry, making the production of precise and complex parts easier. Fortunately, there’s still more to come, and that’s what we hope to explore in this article. Understanding the future of CNC machining is crucial as advancements like automation and robotics are reshaping the industry, driving efficiency and innovation in […]

Choosing an injection molding provider is a decision that involves carefully addressing several key questions. Are their parts of superior quality? How responsive is their customer service during potential issues? Are their products environmentally friendly? Moreover, as the industry is on a growth trajectory—expected to swell from USD 285.5 billion in 2023 to USD 358.1 […]

Casting is important technology used in different manufacturing sectors, from the automotive to aerospace field, and that’s because it’s a more cost effective option. Beyond being more affordable than many alternative manufacturing methods, casting also ensures exceptional optical purity. In this article, we’ll discuss the casting process in detail and applications where it’s highly needed. […]

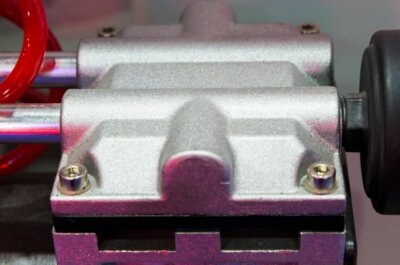

A CNC machine is invaluable because it seamlessly automates the machining process, therefore efficiently enabling the production of high quality manufacturing parts. Understanding the parts of a CNC machine is an ever learning process for even operators as they still spend time fine tuning their skills. However, you cannot master what you do not understand, […]

Titanium anodizing is a surface finishing process that not only enhances durability and corrosion resistance, but also boosts the cosmetic appearance of products and aesthetic appeal of titanium components. This technique is especially popular in industries where both strength and appearance are critical, such as aerospace and medical devices. CNC machining often uses anodized titanium […]

Anodizing is important in manufacturing because that’s the final stage to getting a flawless finishing when working with metals like aluminum and titanium. Anodizing is used for surface finish in CNC machining, contributing to the overall functionality and longevity of the products. This article describes the process involved in anodizing from start to finish, and […]

CNC machinists are very important for the manufacturing industry, operating CNC machinery to produce precision parts and components. These professionals transform raw materials into finished products through machining processes like cutting, milling, and turning. CNC machinists ensure the creation of high-quality products used in various sectors, including aerospace, automotive, and healthcare. Their expertise not only […]

Production CNC machining involves the specialized use of CNC (Computer Numerical Control) technologies geared specifically for high-volume manufacturing. This approach to CNC machining harnesses both computer-aided design (CAD) and computer-aided manufacturing (CAM) to achieve precision and efficiency in creating numerous parts with minimal variance and higher throughput rates compared to traditional methods. How Does Production […]

Drilling machines come in different types and they all have their unique functions and applications. From the CNC drilling machine to the gang drilling machine, each type has its own pros and cons. It’s no surprise that you might get confused on the right type of drilling machine to use for your project. As a […]

For beginners, CNC machining can seem like a big, complex world, but in reality it isn’t, and it can be mastered like any other skills. The concept of CNC machining is pretty cool, from programming a CNC to watching it excecute that command to cut metal in precise and accurate parts. However, it can’t be […]

Mastering CNC machining is challenging but definitely not impossible. As a newbie, you might feel it’s a bit out of your reach, but that’s quite far from the truth. CNC machining skills are built upon consistency and hard work, and the best part is that mastering CNC machining opens you up to a world of […]

CNC machining is gaining strong ground in the robotic industry, as more potentials are being realized, including increased productivity and better efficiency. One of the major reasons why robotics is so successful today, is because of its CNC machining integration, and we’d be looking at all of that in this article. We’ll focus on the […]

When it comes to utilizing CNC technology for education purposes, it’s easy to go wrong. Oftentimes, you’ll get to see machine tools sitting idle in universities or colleges, and this is mostly because the wrong equipment was purchased. With CNC, students get the opportunity to tackle real-life challenges using modern digital fabrication tools. This article […]

NC machining and CNC machining use similar concepts as they are both automatic machines utilized in cutting and shaping metals. NC gives you the option of storing data during the machining process, while CNC offers you more flexibility and capacity in handling logical operations. In this article, we’ll define NC machining, its working principles, types, […]

Undercut machining allows you access to parts such as molds and dies that standard machining methods cannot. This article aims to focus on the basics, types and applications of undercut machining, so you’ll have a better understanding. What is Undercut in Machining and Manufacturing? Undercut machining refers to the process where material is removed from […]

Machining thread is an aspect that cannot be skipped in production as it impacts the functionality and integrity of your product. Screws and threads are both important in metalwork, and if part of the goal is to maximize profit, then no manufacturer should take it for granted. This article focuses on thread machining, different types, […]

When it comes to CNC machining operations, SFM is used for describing tool head speed. However, prior to using any machining process, you need to understand how it works. Every machining tool has its set baselines, and adhering to them is what makes your machining process smooth. This article covers all you should know about […]

Setting your CNC machining parameters ensures the utmost perfection of your designs. Although there are multiple parameters in CNC machining, once you have mastered them, they become fairly easy to set and adjust. In this article, we have compiled a list of all the parameters you’ll need, and how to set them to achieve high […]

Wire EDM (Electrical Discharge Machining) is a precise machining process that uses electrical discharges, or sparks, to cut metal. This technology stands out due to its ability to cut intricate contours or cavities in pre-hardened steel without the need for heat treatment to soften and re-harden them. In this article, you will learn about how […]

Swiss machining, a highly specialized area of manufacturing has an important role in producing precision parts essential for various industries. This guide will explore the intricacies and advantages of Swiss style machining, providing a comprehensive look at its mechanics, applications, and unique features. You will understand why Swiss machining is chosen for complex and precise […]

Milling operations are fast becoming a necessity in the manufacturing world. From transforming raw materials into desired shapes, milling operation plays a fundamental role in modern applications – including aerospace and automotive industry. What is a Milling Operation? A milling operation involves using a machine equipped with a rotating cutting tool to remove material from […]

For many prototyping, machining and manufacturing projects, laser cutters should be your go-to process. Laser cutting is far ahead in the fabrication process, as not a lot of other processes can deliver precise cuts at a fast pace. Laser cutting is easily becoming one of the most popular method for cutting large pieces of materials […]

Not all manufacturing processes require the use of heat, and the waterjet cutting method is a proof of that. With the advancement of technology, manufacturing isn’t as tedious as it once was, and that’s because procedures like waterjet cutting are utilized. To achieve accelerated production, reduction in waste materials, and better quality, many manufacturing industries […]

In today’s fast-evolving global market, standing out for quality and efficiency is a necessity. ISO 9001:2015 not only sets the foundation for quality assurance but also acts as a critical tool for businesses aiming to enhance their operational efficiency and global competitiveness. What Is ISO 9001:2015? ISO 9001:2015 is a globally recognized standard that outlines […]

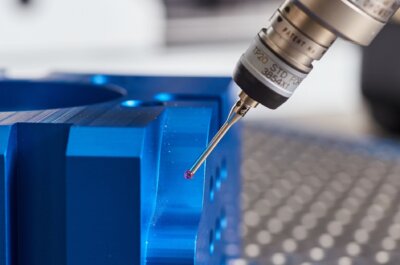

When talking about precision in modern manufacturing, we can’t skip coordinate measuring machine (CMM) inspection, a process that has revolutionized the way industries measure and ensure the quality of their products. This guide will walk you through the world of CMM inspection, unveiling its workings, types, benefits, and much more, providing you with a detailed […]

Building from scratch can be daunting if you don’t know where to start, and you might even end up spending recklessly in the long run. Bridge production and manufacturing is just a temporary ground for industries to continue production pending when they are ready to adopt a permanent production process. It’s all about using 3D […]

CNC machining is necessary in the energy sector as it plays a key role in the development of renewable energy systems. This article explores how this manufacturing process catalyzes advancements in energy production, particularly focusing on its applications across various energy domains. How is CNC Machining Involved in the Energy Industry? CNC machining has become […]

CNC machining opens up an unlimited range of possibilities for materials like glass, transforming raw panes into meticulously crafted products. This article delves deep into the art and science of glass CNC machining, exploring its techniques, benefits, and the diverse applications it supports. Can Glass Be CNC Machined? Yes, glass can indeed be machined using […]

When you think about bronze, images of ancient sculptures and coins might come to mind. However, bronze’s utility extends far beyond artifacts; it plays a crucial role in modern machining. This guide dives deep into the world of bronze machining, exploring its processes, applications, and best practices. What is Bronze Machining? Introduction to Bronze and […]

Composite CNC machining stands at the forefront of this modern manufacturing, offering groundbreaking possibilities in material engineering and production efficiency. This article delves deep into the intricacies of composite CNC machining, examining everything from the fundamental properties of composite materials to advanced machining techniques and their applications across various industries. What are Composite Materials? Composite […]

When stepping into the complex world of manufacturing, First Article Inspection (FAI) emerges as a pivotal process, ensuring that every gear in the production line meshes perfectly from the get-go. This critical evaluation acts not just as a checkpoint, but as a blueprint for future production standards, ensuring that every product meets stringent quality requirements […]

Imagine a world where every product you use is not only cost-efficient but also impeccably designed to enhance its functionality and longevity. This is the heart of Design for Manufacturing (DFM), a crucial approach in modern manufacturing that ensures products are designed with ease of manufacturing in mind, optimizing every aspect from material usage to […]

In today’s manufacturing landscape, reducing CNC machining costs and parts expenses is essential for staying competitive. CNC machining offers precision and efficiency, but it can be costly. This article focuses on practical strategies to minimize these costs, providing you with actionable insights to optimize your manufacturing budget without compromising quality. What Factors Influence CNC Machining […]

Zinc machining plays a pivotal role in various industries, thanks to zinc’s unique properties that make it ideal for machining processes. Its importance stems from its versatility, cost-effectiveness, and corrosion resistance, making it a preferred choice for manufacturing precision components. Understanding Zinc and Its Alloys Zinc, a versatile metal widely used in machining, possesses unique […]

Nickel and its alloys with their unique properties offer solutions to challenging industrial applications. However, machining nickel alloys is not without its hurdles, requiring specialized knowledge and techniques to navigate its complexities successfully. What is Nickel? Nickel, symbolized as Ni with an atomic number of 28, is a hard, malleable, and ductile metal with a […]

Steel CNC machining offers a wide array of applications across industries, embodying the synergy between advanced technology and the timeless strength of steel. Steel CNC Machining stands out for its ability to produce complex geometries with tight tolerances, making it indispensable in industries where precision is non-negotiable. From automotive to aerospace and medical devices, the […]

Metal CNC (Computer Numerical Control) machining involves using computer-controlled machine tools to shape metal pieces into final products or components. In this article we will help you understand metal machining processes, technologies, and how to make the most of its capabilities. What is Metal CNC Machining? Metal CNC machining is a sophisticated manufacturing process where […]

In the world of advanced manufacturing and engineering, certain materials like Inconel stand out for their remarkable properties and the challenges they present during machining. Inconel, a name synonymous with strength, durability, and resistance to extreme environments, is one such material. This guide dives deep into the intricacies of Inconel machining, offering insights and strategies […]

The CNC machining process is a great way to turn innovative designs into precise working models. However, users can only enjoy the full advantages of the process if they use the right CNC machining materials. Using the most suitable material can produce products that exceed your expectations. In contrast, not choosing the best CNC machining […]

In the realm of medical advancements, CNC machining revolutionize the manufacturing of medical devices with unparalleled precision and reliability. Below you will go into the world of CNC machining for the medical industry, exploring its suitability, methods, materials, applications, advantages, challenges, and guidelines for selecting the best CNC machine suppliers. What Makes CNC Machining Suitable […]

When you consider the evolution of manufacturing within the automotive industry, CNC machining stands out as a transformative technology. In this article, we discuss the relationship between CNC machining and automotive manufacturing, exploring how this technology has revolutionized the production of car components, enhanced performance, and introduced a new era of manufacturing precision and efficiency. […]

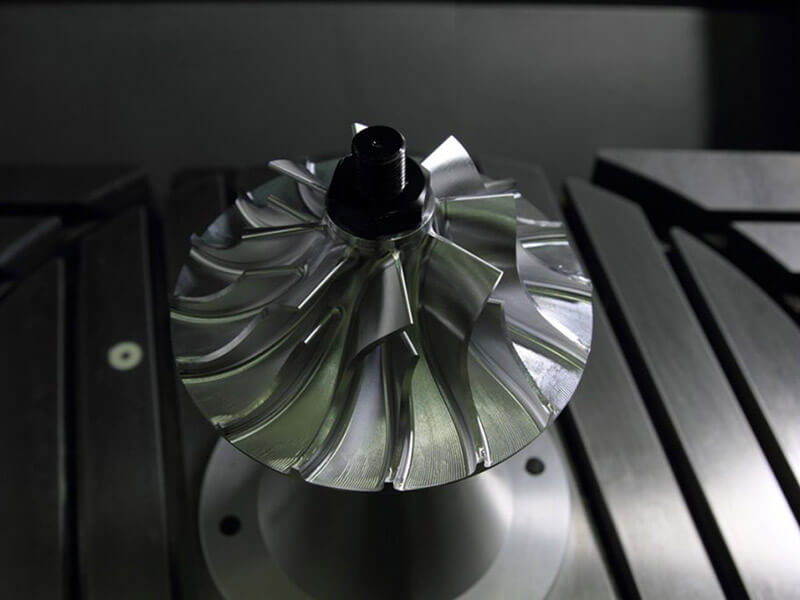

The aerospace industry, a titan of modern technology and innovation, relies heavily on precision and efficiency. Central to achieving these attributes is CNC machining, a process that significantly enhances the production of critical aerospace components. This introduction explores how CNC machining is not just a part of the aerospace industry but a pivotal element in […]

Exploring the universe of machining materials opens doors to an array of possibilities and challenges in the manufacturing sector. In this article we want to emphasize materials suitable for conventional machining, setting them apart from those used in CNC machining. Our journey will cover everything from the historical evolution of these materials to future trends […]

The injection molding process is not without its challenges, particularly when it comes to defects that can compromise quality. Recognizing and addressing injection molding defects is essential for manufacturers to ensure product quality, reduce waste, and optimize production efficiency. This guide goes deep into the most common issues, offering insights into their causes and outlining […]

Acrylic (PMMA) is a highly desirable material due to its strength, toughness, and transparency. But relying on conventional machining processes to cut acrylic can be a complicated procedure: the material is highly fragile and any excess force can cause unwanted breakages. CNC machining, however, offers a reliable way to fabricate acrylic parts safely, with a […]

Rapid injection molding method is revolutionizing how products come to life, blending efficiency and speed with engineering. This process makes it possible to manufacture many durable consumer and industrial items cheaper than everything else. It produces around 32% of plastics by weight. What is Rapid Injection Molding? Rapid injection molding is a type of injection […]

Diving into the world of manufacturing, one cannot overlook the pivotal role of injection molding machines. These devices are the unsung heroes behind the multitude of plastic products we use daily. From simple household items to intricate automotive components, the versatility and efficiency of injection molding machines make them indispensable in the production landscape. What […]

In the vast world of manufacturing, injection molding stands as an essential technique, used for creating a myriad of products with precision and efficiency. Let’s explore the multifaceted types of injection molding processes, each tailored for specific applications, materials, and advantages. The essence of injection molding, a process marrying innovation with technology, propels industries forward, […]

For every CNC machining project, achieving the ideal surface finish is more than just an aesthetic choice—it’s an important factor that influences the functionality, durability, and performance of the machined parts. This comprehensive guide delves into the nuances of CNC surface finishes, offering insights into processes, comparisons, and the selection of suitable finishes for various […]

In the realm of modern machining, CNC drilling stands as a cornerstone, blending precision with efficiency to revolutionize how we create. This article delves into the essence, workings, and vast applications of CNC drilling, offering insights into its types, operations, and the machinery that powers it. Join us as we explore the intricacies of CNC […]

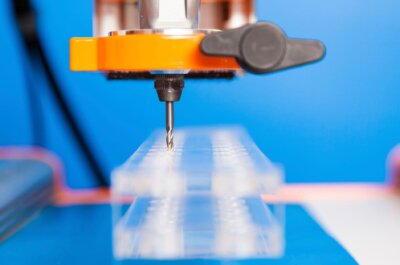

CNC routing stands as a pivotal advancement in manufacturing, offering unparalleled precision and versatility. This article delves into the essence, history, workings, and impact of CNC routing, a cornerstone in modern fabrication techniques. What is CNC Routing? At its core, CNC routing is a type of CNC machining process that utilizes computer numerical control to […]

In today’s fast-paced and increasingly customized world, low volume manufacturing stands as a beacon of flexibility and innovation. This manufacturing approach, unlike its high-volume counterpart, allows businesses to produce smaller quantities of products, catering to specific market demands and niches. In this extensive exploration, we’ll dive deep into what low volume production is, its significance, […]

Electrical Discharge Machining (EDM) represents a fascinating fusion of electricity and precision engineering, revolutionizing how we approach manufacturing complex components. This article aims to demystify EDM, a technique less familiar yet integral to modern manufacturing, by exploring its processes, applications, and evolution. From intricate aerospace components to delicate medical devices, EDM’s role is pivotal in […]

In the realm of machining and metalworking, the grinding machine stands as a pivotal tool, central to shaping and refining a multitude of materials. This article delves into the essence of grinding machines, unraveling their history, mechanism, types, and applications in a detailed exploration. What is a Grinding Machine? A grinding machine, often known as […]

In the realm of manufacturing and engineering, the term ‘surface finish’ plays a pivotal role. Often referred to as surface texture, this concept embodies the array of physical properties and characteristics defining the final appearance and feel of a product’s surface. Whether it’s about ensuring aesthetic appeal or meeting functional requirements, understanding surface finish is […]

CNC grinding, a process that marries the precision of computerized numerical control with the intricate world of grinding, stands as a cornerstone in modern machining operations. This guide delves deep into the realm of CNC grinding, exploring its history, mechanisms, and the myriad of applications it serves in today’s manufacturing landscape. Just as water is […]

Quality testing and inspection in CNC machining applications represent a critical phase, ensuring every machined component meets the high standards of precision and excellence. This article dives into the intricate world of quality testing and inspection, elucidating its significance, methodologies, and the innovations shaping its future. What is Quality Testing and Inspection in CNC Machining […]

In an era where precision and efficiency are a must, small batch machining stands out as a cornerstone of modern manufacturing. This article delves into the intricacies of small batch CNC machining, exploring its evolution, processes, and its pivotal role in today’s production landscape. What Is Small Batch Machining? Small batch machining, a type of […]

When delving into the world of machine tools, the lathe stands out as a fundamental and versatile device. Its ability to shape materials into precise forms has been pivotal in numerous industries, from intricate watchmaking to robust aerospace components. This extensive guide aims to unravel the intricacies of the lathe, exploring its history, functioning, types, […]

The world of modern machining is a realm where precision meets innovation, and at the heart of this technological marvel lies the CNC Lathe – a cornerstone in advanced manufacturing. This article delves deep into the essence of CNC lathes, exploring their history, functionality, types, and much more, unraveling the complexities of these sophisticated machines. […]

Grinding, a term synonymous with precision and efficiency in material removal, stands at the forefront of modern manufacturing techniques. This article delves into the grinding process, exploring its mechanics, applications, and evolution. What is Grinding? Grinding is an intricate abrasive machining process involving an abrasive wheel as a cutting tool. It’s renowned for its ability […]

Computer Numerical Control (CNC) machining stands as a cornerstone in modern manufacturing, a process where pre-programmed software dictates the movements of factory tools and machinery. The precision and efficiency of CNC machining and modern CNC milling tools have revolutionized production, yet the intricate nature of these operations brings inherent challenges, notably in the form of […]

Thermoplastic injection molding offers a versatile and efficient method for mass-producing plastic parts. This guide delves into the intricacies of this technique, exploring its applications, advantages, and the science behind turning raw plastic into durable, functional components. What is Thermoplastic Injection Molding? Thermoplastic injection molding is a transformative process where thermoplastic polymers are melted, injected […]

Injection molding and urethane casting posses unique attributes and applications, shaping the world of production in distinct ways. Injection molding, a method known for its precision and efficiency in mass production of plastic products, contrasts sharply with urethane casting, celebrated for its flexibility and suitability for low-volume production This article delves into the depths of […]

Injection molding and extrusion stand as pivotal manufacturing processes in the plastic industry, each with unique characteristics and applications. In this detailed exploration, we aim to dissect these methods, highlighting their distinct nature and operational principles. These processes, fundamental in shaping countless products around us, from intricate medical devices to robust automotive parts, represent the […]

The manufacturing world stands at a crossroads where precision meets innovation, particularly in the realms of Injection Molding and CNC Machining. Injection Molding and CNC Machining, while seemingly similar, operate on fundamentally different principles. Injection Molding, akin to casting, molds molten materials into predefined shapes. CNC Machining, in contrast, subtracts material through cutting and drilling […]

In the realm of manufacturing, particularly in the plastics industry, the durability and longevity of injection molds are pivotal for efficient production. Understanding the life expectancy of these molds is not just about numbers; it’s about grasping the intricate dance of material, design, and maintenance that dictates their lifespan. This article dives deep into the […]

The world of manufacturing was forever changed with the advent of injection molding, a groundbreaking technique crucial in shaping today’s plastic production landscape. This article delves into the rich history and transformative impact of injection molding, tracing its roots and exploring its pivotal role in the modern plastics industry. What Is Injection Molding? Injection molding […]

In the realm of manufacturing, injection molding tooling stands as a pivotal process, central to the production and manufacture of countless plastic components. This guide delves into the intricacies of injection molding tooling, unraveling its complexities and highlighting its significance in modern manufacturing. What is Tooling in Injection Molding? Injection molding tooling refers to […]

In the realm of modern manufacturing, CNC machining emerges not just as a method, but as a monumental shift in production philosophy. This technology, marrying the precision of computer algorithms with the robustness of machine tools, has not just enhanced but redefined the parameters of production. From its nascent sketches on paper to its current […]

Injection molding stands as a cornerstone in the manufacturing world, revolutionizing the production of parts across a myriad of industries. This method, known for its efficiency and versatility, shapes the way products are created, from everyday household items to intricate components in specialized fields. Injection molding, a manufacturing technique revered for its precision and scalability, […]

Copper, renowned for its electrical and thermal conductivity, plays a pivotal role in modern manufacturing and is a common material used in CNC machining. This guide delves deep into the world of copper machining, unraveling its intricacies, techniques, and applications. It’s not just about shaping a metal; it’s about harnessing copper’s unique properties to create […]

CNC Turning, or Computer Numerical Control Turning, is an important part of modern CNC machining processes and operations. This technology harnesses the precision of computer programming to manipulate lathe machines, transforming raw materials into meticulously crafted parts. CNC turning’s essence lies in its ability to produce cylindrical components with intricate details and high precision. At […]